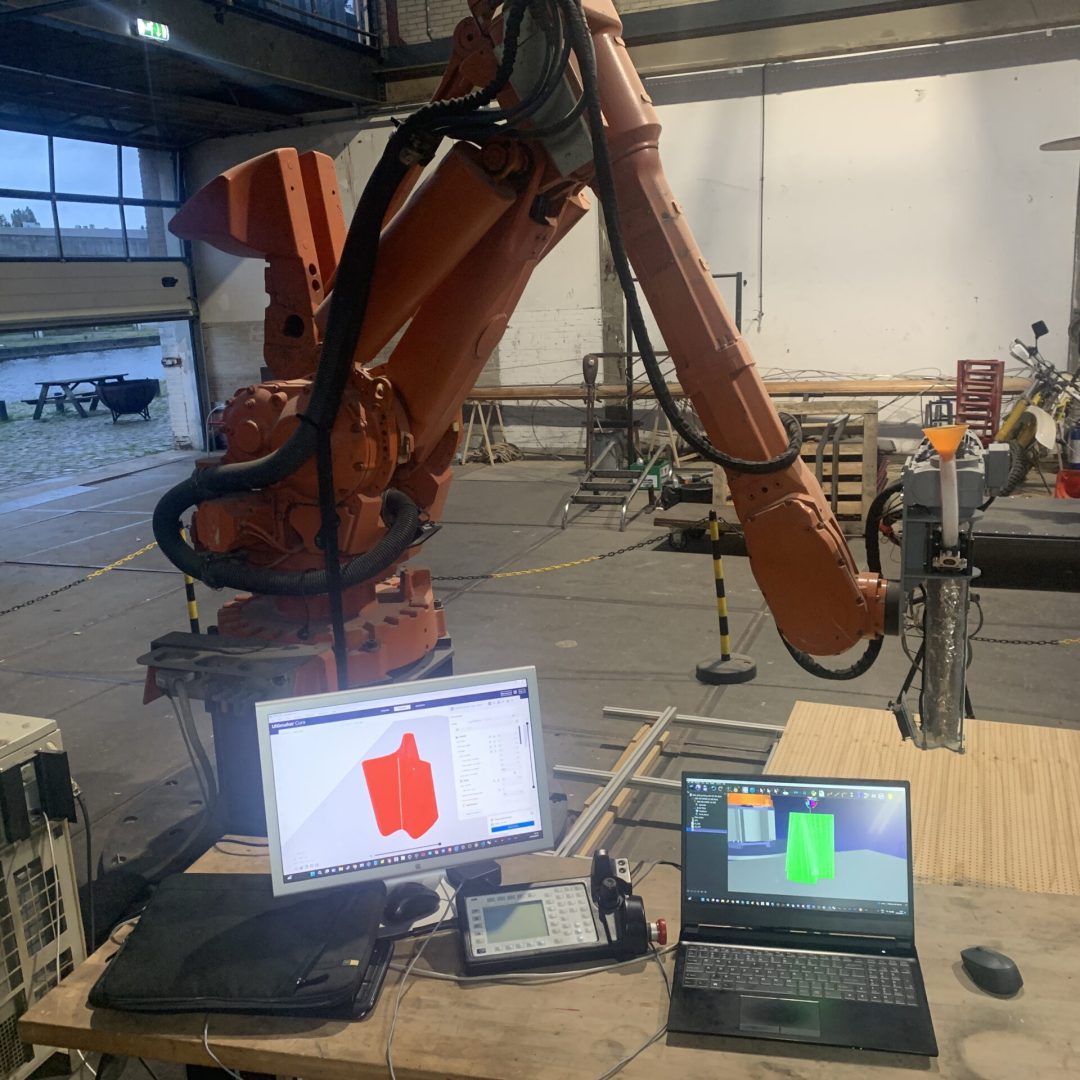

We are currently exploring 3D fabrication methods using industrial robotics

Robot system overview

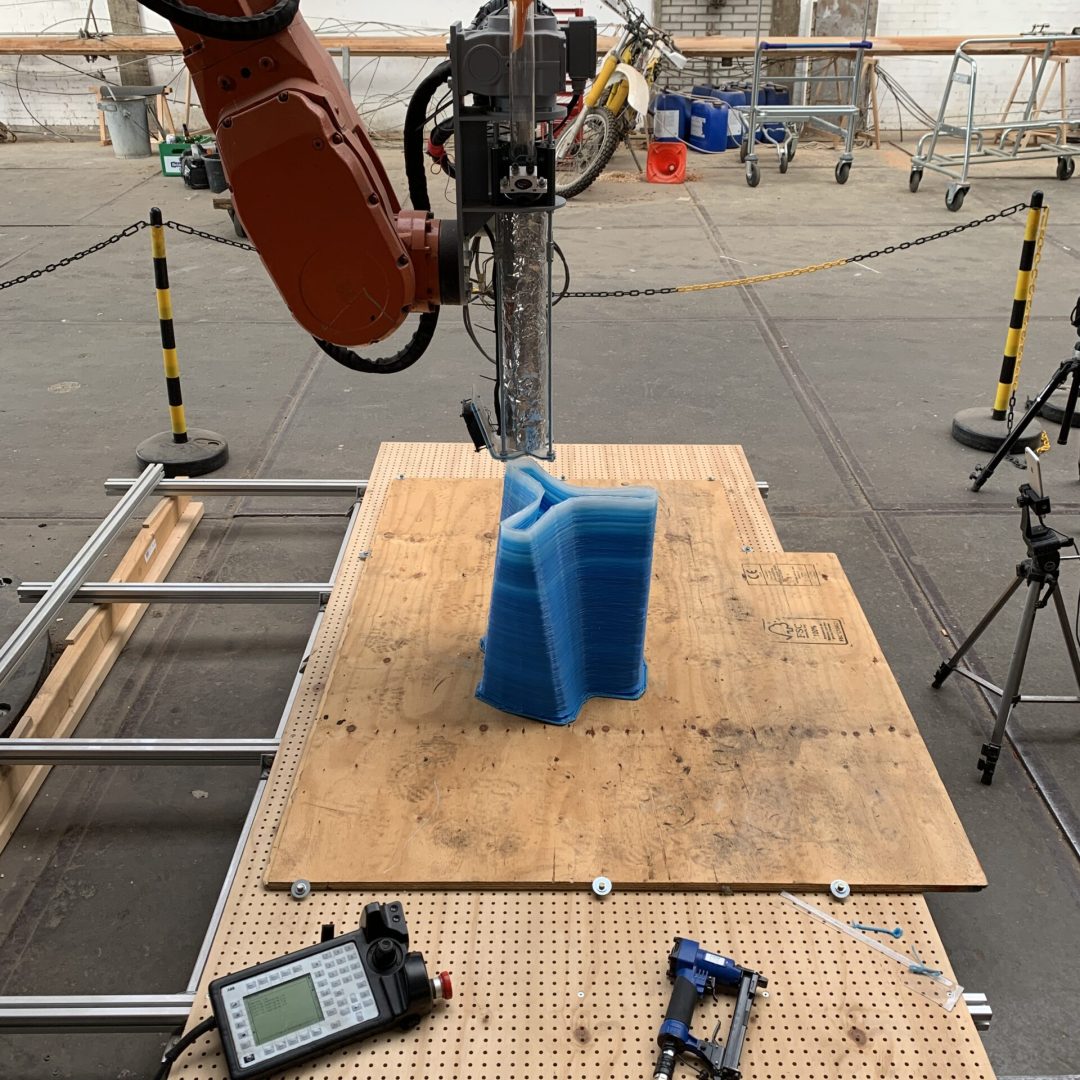

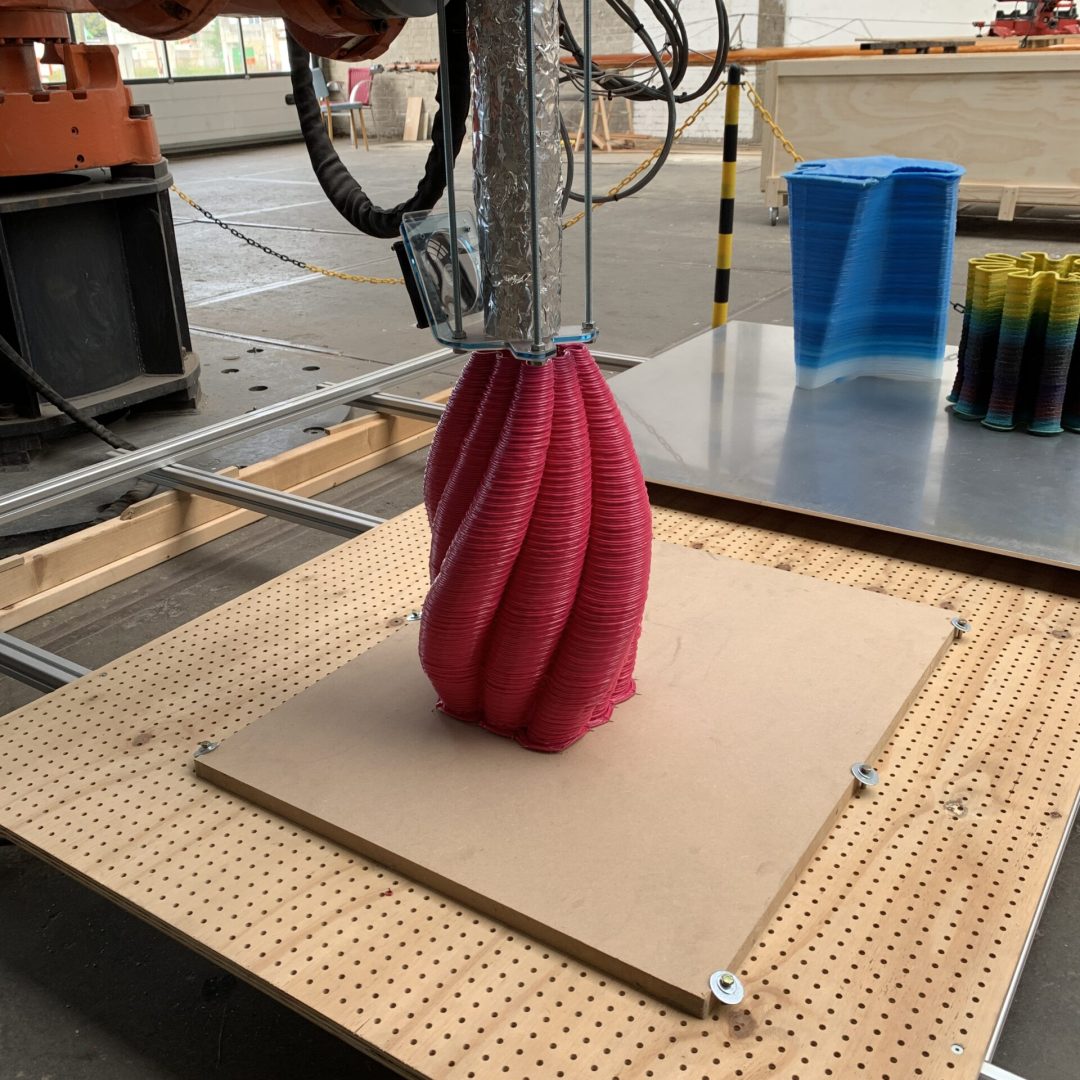

Our Robot is currently equipped with an continuous plastic extruder that uses plastic pellets and flakes so we can print a range of post production or waste plastics.

We can print a variety of geometrie for example furniture, interior objects, wall divider, panels. with in the parameters of our robot stack.

We have a build envelope of roughly 1 x 1.8 x 2 meters in height. Split setup Heatbed 1.2 X1.2 meters

Future Craft Workshop launching summer 2025

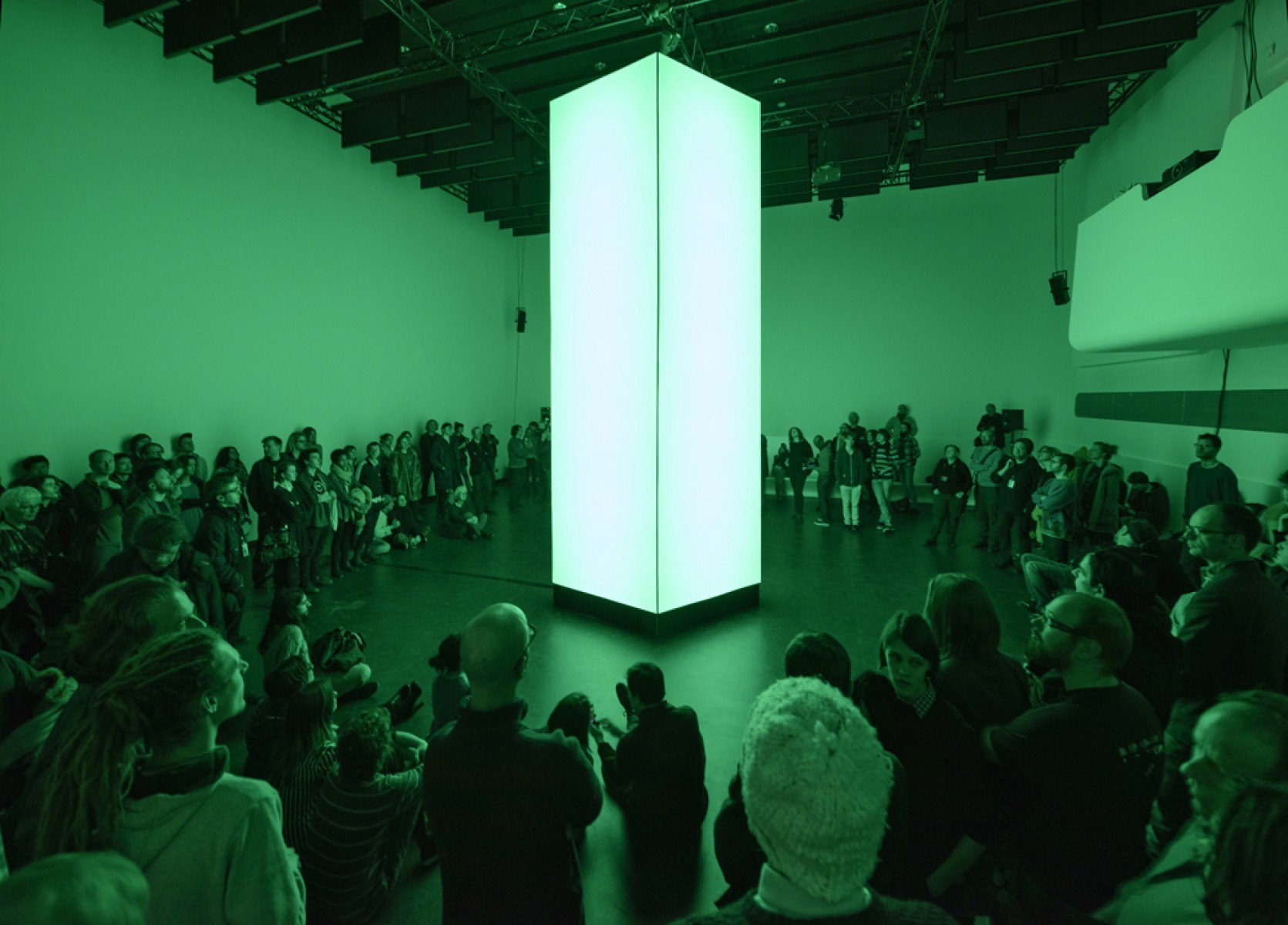

An important driver for the workshops is to make people excited about crafts and manufacturing so we can help shape our exciting future together. We offer 3 part workshop and teach other makers, designers, thinkers and people alike, how you can incorporate automation and robotics in your design workflow and 3D fabrication processes. We provide a research and experimental environment were you can learn valuable information you need to know on how you can apply it to your design pipeline and manufacturing workflow. Join us and subscribe on our social channels. There is a Paypal button below for a short list so we know how many interest there is.Tell us a about your background what projects your working on so we now what interest you and tell us how you could apply robotics to your design and manufacturing workflow!

Difficulty Level

Design Course || Training location The Hague || In this introductory course you will learn what hardware software stack you can use to enroll with robotic manufacturing. We will give you an overview of the robot manufacturing pipeline currently on site.

Difficulty Level

Operator || Training location The Hague || You will gain comprehensive knowledge about a robot cell, production hardware and its interface. We provide you with basic knowledge and workings with an Abb industrial robot.

Difficulty Level

Integrator || Training location The Hague || We will need to dive in some code, and wiring up electronics, motors, sensors to build out a system as you envision. We will guide you trough the process so you understand the basics of offline programming like simulation of robot cell tool integration, and much more.

This payment of euro 10,- is to reserve a seat on a short list so we know if there is enough interest . This amount wil be deducted from the total cost of the workshop! We aim to keep the courses accessible for student artist makers and tinkerers. updates about the development of the course and its cost wil be posted here on the website. to be continued….

We are a young company passionate about art, design and engineering. Our working process is characterized by 3D manufacturing technology. We work with a variety of skills physical and digital,with the current focus on parametric design software and computer aided manufacturing strategies with industrial robotics.

words from our clients

Marcel Kerkmans

Rex

Tuft

Studio Adress

Saturnusstraat 91

2516AG The Hague

The Netherlands

© robots in design. All Rights Reserved.